Startseite » Metal Recycling » Chips » Pump transport and processing

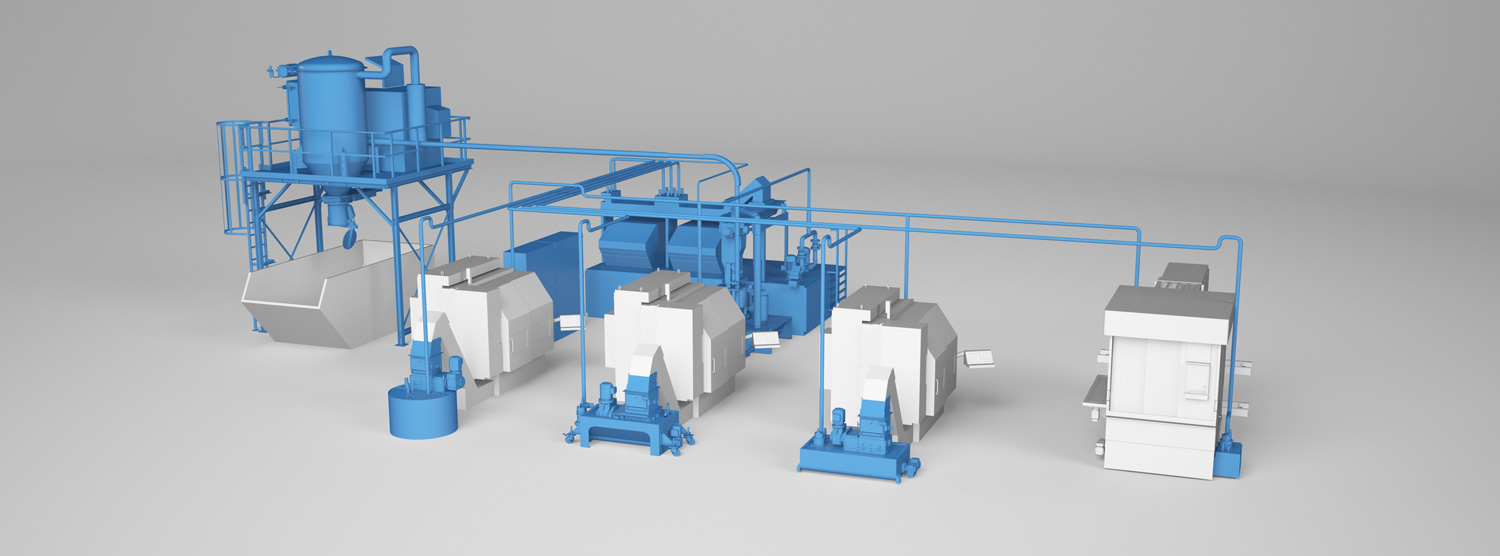

Moist or wet chips are pumped out of the production machine fully automatically and conveyed to the processing plant where they are separated from the cooling lubricant and dried. After processing, the chips are conveyed to space-saving storage containers. The recovered cooling lubricant can be fed back to the production machines after passing through appropriate filter technology and the internal transport with the chip trucks can be completely dispensed with. After optimum processing with the ARP systems, the chips can be sold to waste disposal companies at a significant premium.

The system offers a large number of options to meet your specific requirements